At present, America and Europe etc, developed countries have put forward a higher and newer request to the products of the mesh belt furnace, especially to the security products such as locomotive standard component, the high strength steel construction fastener the advanced chain and advanced close bearings etc. So it lead to a higher level to the heat treatment equipment, our company has developed a set of higher—level software—central control system.The allocation as follows:

SUMON bell type annealing furnace are designed for process reliability, productivity and profitbility.

Heating method: electric heating or natural gas heating; Protection atmosphere: hydrogen and nitrogen; Loading capacity: 20-60 tons

Bell annealing furnace can be divided into two types: vacummized and unvacummized. In principle we don't recommend to use vacumm furnace while diameter is over than 2.2 m.

| Type | Usable Diameter A | Usable Height C | Inner bel Diameter B | Heating bel Diamete D | Crane Hoo height L | M | J | G | H |

|---|---|---|---|---|---|---|---|---|---|

| SB-100/160 | 1000 | 1600 | 1200 | 2500 | 6500 | 600 | 3500 | 3100 | 1600 |

| SB-100/200 | 1000 | 2000 | 1200 | 2500 | 7300 | 600 | 3500 | 3100 | 1600 |

| SB-140/200 | 1400 | 2000 | 1600 | 2900 | 7400 | 600 | 4300 | 3470 | 1970 |

| SB-140/240 | 1400 | 2400 | 1600 | 2900 | 8200 | 600 | 4300 | 3470 | 1970 |

| SB-140/270 | 1400 | 2700 | 1600 | 2900 | 8800 | 600 | 4300 | 3470 | 1970 |

| SB-140/300 | 1400 | 3000 | 1600 | 2900 | 9400 | 600 | 4300 | 3470 | 1970 |

| SB-160/200 | 1600 | 2000 | 1800 | 3100 | 7500 | 600 | 4700 | 3650 | 2150 |

| SB-160/240 | 1600 | 2400 | 1800 | 3100 | 8300 | 600 | 4700 | 3650 | 2150 |

| SB-160/270 | 1600 | 2700 | 1800 | 3100 | 8900 | 600 | 4700 | 3650 | 2150 |

| SB-160/300 | 1600 | 3000 | 1800 | 3100 | 9500 | 600 | 4700 | 3650 | 2150 |

| SB-180/200 | 1800 | 2000 | 2000 | 3300 | 7500 | 600 | 5100 | 3850 | 2350 |

| SB-200/200 | 2000 | 2000 | 2200 | 3500 | 7750 | 700 | 5500 | 4000 | 2500 |

| SB-200/240 | 2000 | 2400 | 2200 | 3500 | 8750 | 700 | 5500 | 4000 | 2500 |

| SB-200/270 | 2000 | 2700 | 2200 | 3500 | 9250 | 700 | 5500 | 4000 | 2500 |

| SB-200/300 | 2000 | 3000 | 2200 | 3500 | 9900 | 700 | 5500 | 4000 | 2500 |

| SB-245/200 | 2450 | 2000 | 2650 | 3950 | 8050 | 700 | 5900 | 4200 | 2700 |

| SB-245/240 | 2450 | 2400 | 2650 | 3950 | 9050 | 700 | 5900 | 4200 | 2700 |

| SB-245/270 | 2450 | 2700 | 2650 | 3950 | 9550 | 700 | 5900 | 4200 | 2700 |

| SB-245/300 | 2450 | 3000 | 2650 | 3950 | 10200 | 700 | 5900 | 4200 | 2700 |

| SB-280/200 | 2800 | 2000 | 3000 | 4300 | 8500 | 750 | 6300 | 4600 | 3100 |

| SB-280/240 | 2800 | 2400 | 3000 | 4300 | 9500 | 750 | 6300 | 4600 | 3100 |

| SB-280/270 | 2800 | 2700 | 3000 | 4300 | 10000 | 750 | 6300 | 4600 | 3100 |

| SB-280/300 | 2800 | 3000 | 3000 | 4300 | 10650 | 750 | 6300 | 4600 | 3100 |

| SB-350/200 | 3500 | 2000 | 3700 | 5000 | 8800 | 800 | 7200 | 5500 | 4000 |

| SB-350/270 | 3500 | 2700 | 3700 | 5000 | 10300 | 800 | 7200 | 5500 | 4000 |

| SB-350/300 | 3500 | 3000 | 3700 | 5000 | 10950 | 800 | 7200 | 5500 | 4000 |

| SB-370/250 | 3700 | 2500 | 3900 | 5200 | 10300 | 800 | 7800 | 6100 | 4600 |

| SB-370/290 | 3700 | 2900 | 3900 | 5200 | 11100 | 800 | 7800 | 6100 | 4600 |

| SB-370/320 | 3700 | 3200 | 3900 | 5200 | 11700 | 800 | 7800 | 6100 | 4600 |

| SB-370/360 | 3700 | 3600 | 3900 | 5200 | 12500 | 800 | 7800 | 6100 | 4600 |

| SB-370/400 | 3700 | 4000 | 3900 | 5200 | 13300 | 800 | 7800 | 6100 | 4600 |

| SB-390/250 | 3900 | 2500 | 4100 | 5400 | 10350 | 800 | 8000 | 6300 | 4800 |

| SB-390/290 | 3900 | 2900 | 4100 | 5400 | 11150 | 800 | 8000 | 6300 | 4800 |

| SB-390/320 | 3900 | 3200 | 4100 | 5400 | 11750 | 800 | 8000 | 6300 | 4800 |

| SB-390/360 | 3900 | 3600 | 4100 | 5400 | 12550 | 800 | 8000 | 6300 | 4800 |

| SB-390/400 | 3900 | 4000 | 4100 | 5400 | 12350 | 800 | 8000 | 6300 | 4800 |

| SB-410/250 | 4100 | 2500 | 4300 | 5600 | 10450 | 800 | 8200 | 6500 | 5000 |

| SB-410/290 | 4100 | 2900 | 4300 | 5600 | 11250 | 800 | 8200 | 6500 | 5000 |

| SB-410/320 | 4100 | 3200 | 4300 | 5600 | 11850 | 800 | 8200 | 6500 | 5000 |

| SB-410/360 | 4100 | 3600 | 4300 | 5600 | 12650 | 800 | 8200 | 6500 | 5000 |

| SB-410/400 | 4100 | 4000 | 4300 | 5600 | 13450 | 800 | 8200 | 6500 | 5000 |

|

The D,H, values of eletric heating type furnace reduced accordingly

|

|||||||||

The BECON type bell annealing furnace is designed to annealing (soft annealing, spheroidizing, recrystallizing) treatment suitable for all kinds of steel and non-ferrous metal.

High Strength Bolts

Automotives Screws

precise Bearings

Metals Tools

Nuts

Hand Tools

The facility is designed to heat treat all wire (low-carbon, medium-carbon, high carbon), dilute-alloy steels, high carbon alloy, aluminium alloy, brass alloys and Cr-alloyed ferrite and martensite Cr-alloyed steels.

Seeing that annealing in BECON type bell annealers is carried out. All annealing cycle are carried out in process atmosphere (free of decarburization, free of cementite). The annealed drawn wire has achieved Spheroidizing, surface of the annealed drawn wire is bright and very clean. As the material has a very uniform microstructure and It is easier to process on manufacturing machines.

Seeing that annealing in BECON type bell annealers is carried out. The cost reduction owing to

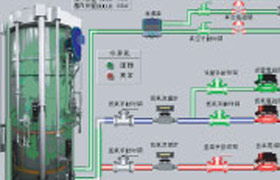

The control system of our bell annealing furnace indue two basic aspects: one is to satisfy the requirement of production facility and technology; The other is to satisfy the manufacture, use and maintenance of the electric and gas control facility.

With the automatic control principle, PC and hardware and software of PLC perfect combine to acheive long-distance control so as to improve quality, productivity and work conditions.

The bell annealing furnace control system of our company is developed by ourselves. This software integrated with surveillance and control of annealing temperature, pressure and electricity and the function of precription setting, recording and looking up production data.

The furnaces on/off running condition and the values of temperature flow, pressure, voltage and electricity can be understand from the windows pictures. Pictures control can solve kinds of problems when abnormity alarms coming, which makes the operator master the condition quickly and handle.

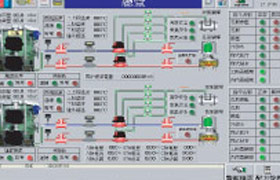

Electric control心

Main Picture

Valve Stands

Monitoring Picture for Combustion System

Overview for Monitoring System

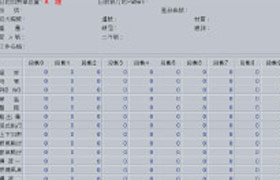

Aging Trends Chart

Monitoring Picture for Cost Analysis Module

Monitoring Picture for Prescription Management

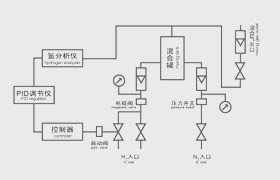

According to the chemical formula, ammonia decomposing gas Is consist of 75% H2 and 25% N2. Its features including: strong deoxidization, little decarburizatlon, no carbon separate out. Dew point is about-60 ℃.

Transformation adsorption nitrogen generator (for short PSA generator) is an advanced gas separating technology. It use imported carbon molecule screen (CMS) as sorbent, with the principle of pressure trasformation and adsorption under nomal temperature to get high purely nitrogen by separating air.

PSA nitrogen generator is a nitrogen generating device desinged and manufactured on the basis of transformation and adsorption technique. Generally two adsorption tower parallel connection and controlled by automatic control system in term of particular programmable program, alternately compressing to adsorb and decompressing to regenerate, then complete nitrogen and oxygen sepa-ratng to get required high purely nitrogen.

After having mixed the hydrogen and nitrogen pro rata, sampling some gas sample into hydrogen analyzer to test the ratio of nitrogen and hydrogen. One side the instrument will display the content of nitrogen and hydrogen, the other side electric signal will be sent to controller to compare with the setting valve of hydrogen. Then through PID regulator to control the opening degree of hydrogen valve to get required setting value of hydrogen.

In order to keep the gas (N2, H2, Gas) supply pressure invariable, we must contorl the gas pressure. Our supplied pressure control system can regulate relevant condition such as pressure, flow meter etc as required.