At present, America and Europe etc, developed countries have put forward a higher and newer request to the products of the mesh belt furnace, especially to the security products such as locomotive standard component, the high strength steel construction fastener the advanced chain and advanced close bearings etc. So it leads to a higher level to the heat treatment equipment, our company has developed a set of higher—level software—central control system.The allocation as follows:

The operation controlled by computer; The functions of lot number management; The function of self—weighing; The infrared value controlled by I/R; Heat treatment expert system. ES; Network distance control; Cost analysis

The full-line equipment of continuous conveyor tempering carburlzing quenching furnace of our company are used to treat all Kinds of fasteners and special parts. The range of heat treatment method Include: quenching, tempering, (may include gas (DX) blackening), carburlzing, etc. According to the characteristic of the furnace, we propose not to use carbonltriding heat treatment method which will Influence the service life of the mesh belt. The Light sheet work piece is apt to overlap and adhere, which will Influence the result of heat treatment and will "lose". So if there are not appropriate precautionary measures,we suggest that it should not be produced In this furnace.

| Type | Total out power (KW) |

Total Length(m) | Size of Quenching furnace | Size of Tempering furnace | |||||

|---|---|---|---|---|---|---|---|---|---|

| Carburing | Quenching | Net width | Heating length | Length of furnace | Net width | Heating length | Length of furnace | ||

| SM-1 E | 220 | 28.5 | 30.5 | 400 | 3.5 | 4.0 | 600 | 3.5 | 4.0 |

| SM-2 E | 400 | 32.5 | 34.5 | 600 | 5.5 | 6.0 | 800 | 5.5 | 6.0 |

| SM-3 E | 450 | 36.5 | 38.5 | 600 | 7.5 | 8.0 | 800 | 7.5 | 8.0 |

| SM-4 E | 550 | 36.5 | 38.5 | 800 | 7.5 | 8.0 | 1000 | 7.5 | 8.0 |

| SM-5 E | 650 | 40.5 | 42.5 | 800 | 9.5 | 10.0 | 1000 | 9.5 | 10.0 |

| SM-6 G | 76000KCAL/1H 100 KW |

44.5 | 46.5 | 1000 | 11.5 | 12.0 | 1200 | 11.5 | 12.0 |

| SM-7 G | 1250000KCAL/1H 110 KW |

49 | 57 | 1200 | 12.5 | 13.0 | 1400 | 12.5 | 13.0S |

| Remark: when annealing furnace allocate with gas blackening, the length should increase 2 meters. | |||||||||

| Type | Carburizing capacity/per month (Tons) | Quenching capacity/per month (Tons) | Carburizing capacity/per hr (Kgs) | Quenching capacity/per hr (Kgs) |

|---|---|---|---|---|

| SM-1 E | 58 | 115 | 80 | 160 |

| SM-2 E | 190 | 270 | 270 | 380 |

| SM-3 E | 210 | 290 | 300 | 410 |

| SM-4 E | 340 | 440 | 480 | 620 |

| SM-5 E | 540 | 610 | 760 | 860 |

| SM-6 G | 670 | 790 | 940 | 1100 |

| SM-7 G | 1000 | 1200 | 1380 | 1600 |

|

||||

A.gas heating system. Advantage: low operation cost and low repair cost no influence when the power out. Key points: high equipment purchasing cost.

B.electric heating system. Advantage: lower equipment purchasing cost. Key points: high operation cost and high repair cost, influenced by the power out.

A.quenching furnace used for carburizing: use anti-carburizing bricks, such as LBK-23, LBK-26 etc, anti-carburizing mesh belt, material SUS310S.

B.quenching furnace used for quenching: may equip with Gas generating furnace. Its C.P control is more accurate than the methanol's, and don't accumulate carbon and don't pollute quenching oil. radiant tube and mesh belt lived - long. Use general fire-resistant and heat-insulated bricks, such as B-5, B-1 etc. mesh belt material: SUS310S.

A.Low temperature furnace:used for carburizing of tempering. Temperature lower than 400℃.

B.High temperature furnace: used for quenching of tempering. Temperature lower than 650℃.

C.Gas blackening tempering furnace: tempering used for gas blackening, temperature470-540℃.

A.traditional Instrument control:Key points: no data record (no reports and history archives)

B.completely central PC base control system:Advantage: record the data. (have reports and history archives).

C.traditional instrument control + central PC base control system: Advantage: there is advantage of completely central PC base control system, and when the computer system halted, can switch to instrument control.

A.O2 Sensor CP control system: Advantage: low purchasing cost. CP is not accurate, and the use life is short, it is easy to accumulate carbon because we can not know the atmosphere composite of the furnace, such as co, co2.

B. Infrared (l/R)Advantage: high dependability, perfect carbon potential control, long performance life, low maintenance cost. Key points: high primary purchasing cost.

A.Gas generating furnace. Advantage: perfect carbon potential control, not easy to accumulate carbon. Key points: high primary purchasing cost.

B.methanol decomposing furnace. Advantage: purchasing cost is lower than Gas generating furnace and lower cirbon accumuation than methanol dripping. Key points: carbon potential control is not perfect.

C.methanol dripping. Advantage: low allocation cost, economical type. Key points: easy to accumulate carbon, carbon potential control is not perfect.

Direct rotary type (hydraulic)

Features: low trouble rate, easy maintenance. operation efficient, simple and convenient. segment unloading. oil pressure power, lifting stablely and safety.

Elevate rotary type

Features: Suit for small lot number.

Vibration Feeder

Features: The thickness of work piece arranged evenly.

Magnetic belt feeder

Features: using excellent magnetic stripe,strong magnetic and long-lived. work piece attracted evenly. Material no fall. conveyor belt weaved by stainless steel wire. can change the angle, replace the old stair j type feeder.

Self—weighing feeder

Features: Ration control: give the material evenly ,the temperature and carbon potential are relatively perfect. Lot number management: prevent mixing material.

Front and rear washing machine (Soating type)

save energy: Utilize the hot water washing circulation of the heat exchanger at the preheating area of the quenching furnace. perfect wash result: oil and water separate, recovery use, environmental protection and energy-conservation. strong hot blast drying design: the surface moisture of work piece is fully died up, prevent the vapor from bringing into the furnace. Equip with inductor. transmission chains: SUS304 stainless steel. loading pattern angle bar use SUS 304 stainless steel.

Front and rear washing machine (Horizontal type)

Economical washing machine

Quenching furnace

cylinder through special design, uneasy to accumulate the carbon. waste outlet: hole clean completely. double systematic exchanger, save energy and low the cost.

quenching furnace used for carburizing: use anti-carburizing bricks and anti-carburizing mesh belt. quenching furnace used for quenching: use general fire-resistant and heat-insulated bricks and anti-carburizing mesh belt.

Dripping lifting machine

Tempering furnace

low temperature tempering furnace: used for carburizing. high temperature tempering furnace: used for carburizing, quenching. gas blackening tempering furnace used for carburizing, quenching, gas blackening.

Anti-rust tempering tank

Multi—functionality : The design of oil water and coloring agent can go on coloring,water—cooling, air cold treatment at the same time.

High safety : Equip with one set of high efficient enery—heat exchanger to automatic adjust to prevent oil temperature too high.

class="img-thumbnail" >

class="img-thumbnail" >

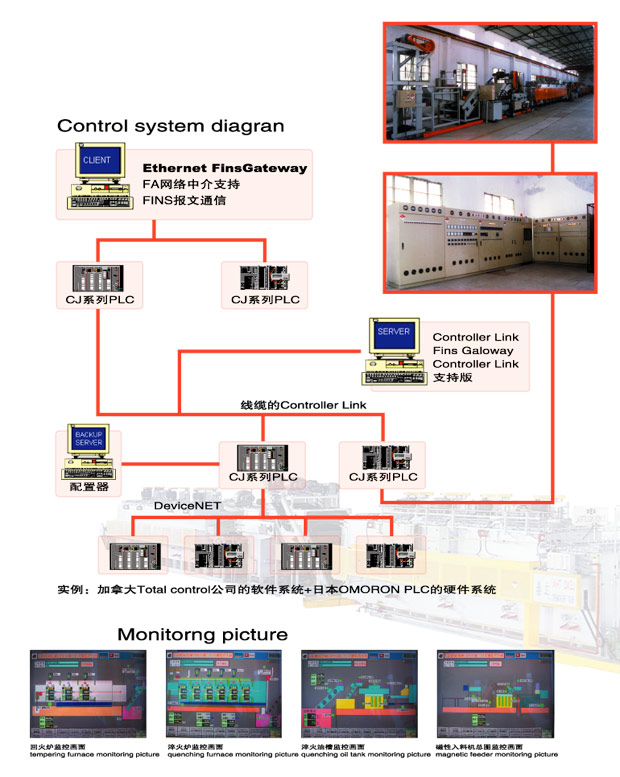

The mesh belt furnace that our company produce , and the control system all Include two basic parts: 1 .satisfy various control demand of production machinery and production technology. 2.satisfy the demand of production* using and repairing for electric control device itself. The control system of our company Is consist of the target, measuring units, controller and regulating valve etc. According to country electronic control norm, apply automatically controlled principle, combine the central PC base contol system with traditional electric PLC software and hardware and give full play to the software function of PC base control system to make systematic technology and economic indicator more superior. Now we have realized the computer distant control the heat treatment production, which favorable to improve quality, production efficiency and work conditions, and it is most advanced central PC Base control system among the counterparts at present.

Integration of control and managemen

The central PC base control system of our company using the most advanced DCS internet system to make the biggest and safest monitoring system.

Distributed control system also named centralized distributed control system is a comprehensive high-tech product that Incorporate with the computer technology .control technology .communication technology .according to the national norm, we use the central PC base contrd system to monitor .operate and manage the whole heat treatment process. The distributed control for heat treatment through PC Is different from the routine Instrument control system and centralized computer control system. It concentrated advantage of the two parts and overcome their deficiency . Liability .flexibility , friendly man-machine Interface and convenient communication are the characteristic of our DCS which is the ideal industrial control system.

DCS system is superior to centralized control system(CCD) on dealing ability and safety. And also superior to traditional instrument control,which is the most advanced high-efficient and reliable real time central PC base control system.

DCS is set up on the basis of internet, the key structure is three points one lines structure, one line means the skeleton computer network of DCS, and three points means the three different kinds of nodes which join in the network:

one DCS only need one engineer station, while the quantity of I/O local control station and operator station equipped many sets according to the demand. Three kinds of nodes connect and exchange information, coordinate the various work and finish the whole function of DCS together through system network.

DCS network topological structure, can use token Ring and token passing.